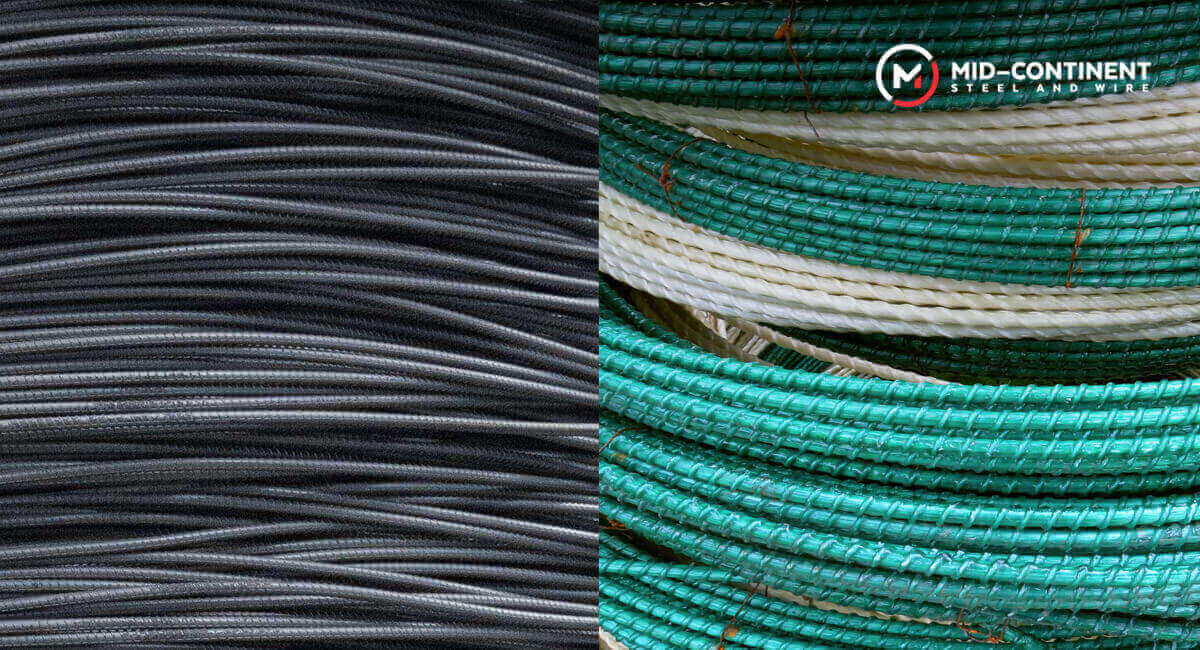

Fiberglass Rebar vs Steel Rebar

Fiberglass rebar and steel rebar have different properties and are suited for different applications.

Overview of Fiberglass Rebar (GFRP)

GFRP stands for Glass Fiber Reinforced Polymer. The polymer matrix is typically a type of plastic, such as epoxy, polyester, or vinyl ester, which distributes loads among them. The glass fibers add strength and stiffness to the material, making it lightweight yet strong. GFRP is commonly used in a variety of applications, including construction, automotive, aerospace, and marine industries.

Overview of Steel Rebar

Short for reinforcing bar, it is typically embedded in concrete to enhance its tensile strength, as concrete alone is strong in compression but weak in tension. Steel rebar provides structural integrity.

Common applications include roads, bridges, buildings, and other infrastructure projects. Its use is fundamental in earthquake-prone regions to improve the ductility and strength of concrete.

Fiberglass Rebar Features

- Material Composition: Made from glass fiber-reinforced polymer, it combines glass fibers with a polymer matrix.

- Corrosion Resistance: Highly resistant to corrosion, ideal for use in harsh environments or structures exposed to de-icing salts, seawater, or chemicals.

- Weight: Much lighter than steel rebar, which makes it easier to handle and transport, potentially reducing labor costs.

- Non-conductive: Does not conduct electricity or magnetic fields, which can be beneficial in structures that require electromagnetic neutrality, such as hospitals and labs.

- Tensile Strength: High tensile strength, but has a lower modulus of elasticity compared to steel, while it can handle significant tensile stress, it is less stiff.

- Thermal Expansion: Similar expansion properties to concrete, which minimizes stress during temperature changes.

- Cost: Usually more expensive than steel rebar.

Steel Rebar Features

- Material Composition: Made from carbon steel, typically with deformations on the surface for better bonding with concrete.

- Corrosion Resistance: Prone to corrosion when exposed to elements like moisture or salts unless treated or coated.

- Weight: Heavier, which can increase the cost and complexity of transportation and installation.

- Conductive: Conducts electricity, making it unsuitable for certain applications where electromagnetic interference needs to be minimized.

- Tensile Strength: High tensile strength with an excellent modulus of elasticity. This means it will deform less under tension compared to GFRP, making it very effective in many structural applications where rigidity is essential.

- Thermal Expansion: The thermal expansion coefficient differs from concrete, which could be a concern in structures exposed to wide temperature variations.

- Cost: Generally more affordable compared to fiberglass rebar, making it a common choice for many construction projects.

It all depends on the application

Both GFRP and steel rebar are great choices for structural integrity. However, your project requirements will determine which option is better.

Steel rebar is more commonly used to reinforce concrete. This is due to several factors:

- Well-Established Industry Standards: The use of steel rebar is supported by construction standards and building codes worldwide, ensuring consistency in engineering practices.

- Mechanical Properties: The high modulus of elasticity of steel provides the necessary stiffness and ability to handle both tensile and compressive forces.

- Availability: Steel rebar is widely available and comes in various sizes and grades, making it suitable for a broad range of construction needs.

Mid-Continent Steel and Wire has a solution for your project

Our rebar is manufactured with the highest quality standards. It is available in straight, coiled, and spooled rebar with different grades and lengths.

Meets: ASTM A615 G40, G60 OR G80 & ASTM A706 for Weldable Bars

We can provide you with solutions for the strongest foundations. Get in touch.