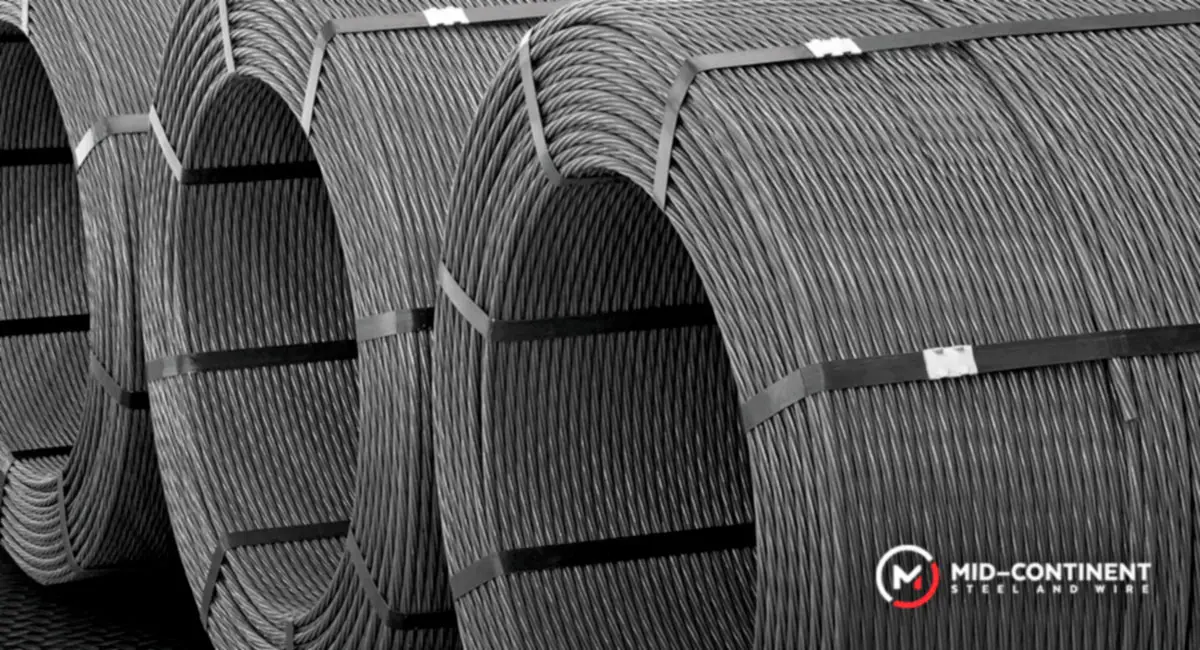

PC strands, or prestressed concrete strands, are high-strength steel wires made up of individual steel wires twisted together in a helical pattern. They are specifically designed to withstand high tensile forces.

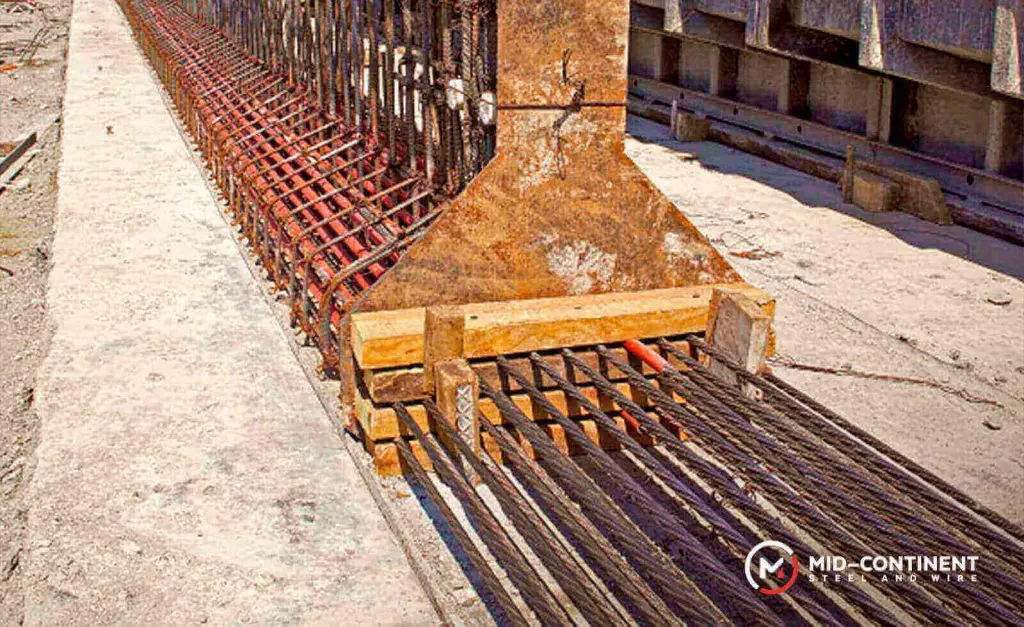

By introducing prestress to concrete, PC steel wire strands help to counteract the tensile forces that it may be exposed to, this can increase the load-carrying capacity. PC strand is widely used with concrete structures such as beams and columns.

Prestressed strands can increase the strength of concrete structures and are often used for large scale projects. Prestressed steel strand construction can vary in diameter, length, and finish.

Construction uses of PC strand

Many construction projects can benefit from prestressed strand and consider it essential in their structure, including:

- Bridges

- Commercial buildings

- Parking structures

- Offshore platforms

- Stadiums

- Highway work

- Mining

- Parking garages

PC strand is a reliable way of adding bond strength to any concrete structure.

Benefits of using prestressed concrete steel strand

- Saves on construction materials: Its design with longer spans and smaller cross-sections make it more economical.

- Withstands rough weather conditions: It can retain its strength and integrity even in harsh environments, with corrosion resistant properties.

- Can carry heavy loads: Its high tensile strength makes it ideal for large structure projects.

- Wide range of sizes and strengths: There are many options in the market to choose from, to fit your project requirements.

Mid-Continent Steel and Wire PC strand specifications

Our uncoated seven-wire PC Strand is manufactured under the highest quality standards. It is used in pretensioned and post-tensioned prestressed concrete constructions.

Construction: 1×7 270 ksi Low-Relaxation

Diameter: 0.50” (0.60” also available as MTO)

Min Elongation: 3.5%

Coil Length: 270 kft

Finish: Uncoated or Galvanized

1000-Hour Relaxation Testing: Successful Completion & Approval of ASTM A1061

Meets: ASTM A416