The performance and resilience of materials are fundamental to the success and longevity of any project. Among the essential components used in building, steel wire plays a fundamental role in structural integrity and adaptability across countless applications. Known for its exceptional tensile strength and flexibility, steel wire is used for countless applications.

Types of steel wire for construction

The construction industry depends on a wide range of steel wire types, each meticulously engineered to meet the demands of specific structural and functional applications. These are some of the most used across different industries:

- Black annealed wire: Known for its high ductility and malleability, black annealed wire is ideal for binding and tying applications.

- Galvanized wire: This corrosion-resistant wire is perfect for outdoor and harsh environment uses, thanks to its protective zinc coating.

- Bright basic wire: Offering excellent strength and finish, bright basic wire is commonly used in chain link fences and shopping carts.

- Spring wire: Engineered for applications requiring high tensile strength and elasticity, such as in furniture and automotive manufacturing.

- Carbon steel wire: A type of steel wire primarily made from iron and carbon. The amount of carbon content typically ranges from low to medium levels, which directly influences the wire’s strength, hardness, and flexibility.

Applications in construction and infrastructure

Welded wire products are utilized in everything from soaring skyscrapers and large-scale roadways to complex public infrastructure systems, depending on their type. It contributes significantly to the durability, stability, and long-term safety of projects. Some of them include:

- Reinforced concrete: Steel wire mesh and rebar provide the necessary tensile strength to concrete structures.

- Fencing and security: Galvanized wire is the go-to material for durable, weather-resistant fencing.

- Scaffolding: Temporary structures benefit from the strength and lightweight nature of steel wire components.

Benefits of steel wire in infrastructure projects

The widespread use of steel wire in the construction industry can be attributed to the numerous advantages it offers across a broad range of applications. Its high tensile strength, flexibility, and durability make it an ideal material for reinforcing structures and providing long-term stability. Some of its benefits are:

- High tensile strength: Steel wire can withstand significant loads, making it ideal for structural applications.

- Durability: Properly treated steel wire can last for decades, even in challenging environments.

- Corrosion resistance: Galvanized and specially coated wires offer excellent protection against rust and corrosion.

- Cost-effectiveness: The long lifespan and relatively low production costs make steel wire an economical choice for large-scale projects.

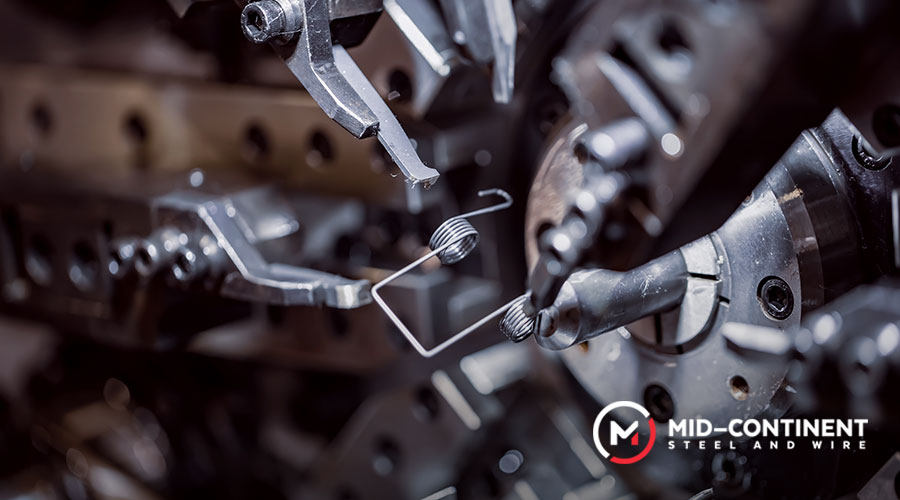

Manufacturing process and quality control

The production of high-quality steel wire involves several critical steps, each carefully designed to enhance the material’s strength, consistency, and performance for demanding applications. Every stage plays a vital role in delivering a product that meets the rigorous standards of the construction and infrastructure industries. These can involve:

- Wire drawing: Raw steel is drawn through progressively smaller dies to achieve the desired diameter.

- Heat treatment: Processes like annealing and patenting alter the wire’s mechanical properties.

- Coating: Galvanization or other protective coatings are applied for enhanced durability.

- Quality control: Rigorous testing ensures the wire meets industry standards for strength, dimension, and finish.

Sustainable manufacturing

As leading steel wire manufacturers across America, we incorporate a range of energy-efficient and environmentally responsible practices into our production. These practices align with sustainability goals and current industry standards. As top wire manufacturers, we contribute to reducing environmental impact in our manufacturing welded wire products. Stainless steel wire suppliers take into consideration:

- Sustainable sourcing: Our products are made with recycled steel as a raw material, which significantly reduces the need for new resource extraction and lowers energy consumption.

- Closed-loop recycling: Scrap produced during manufacturing is recycled back into the process.

- Modern equipment: We use energy-efficient electric arc furnaces to help reduce overall energy use.

- Process optimization: Our streamlined production steps like drawing, welding, and galvanizing help cut down on waste and excess energy use.

Our products can help your project earn LEED credits!

Choosing the right steel wire for your project

Selecting the appropriate steel wire for a given project requires careful consideration of several important factors such as:

- Environmental conditions such as indoor vs outdoor, exposure to chemicals, etc.

- Load requirements and stress factors

- Desired lifespan of the structure

- Stainless steel grades

- Budget constraints

As a leading wire company, you get expert guidance in choosing the optimal product for your specific needs.

The future is wired for success

Mid Continent Steel and Wire stands out from other wire suppliers due to our commitment to delivering high-quality steel wire products that meet strict industry standards. Beyond quality and performance, one of our key strengths is our dedication to sustainable manufacturing practices, exceptional customer service, and guidance. We are your reliable supplier!