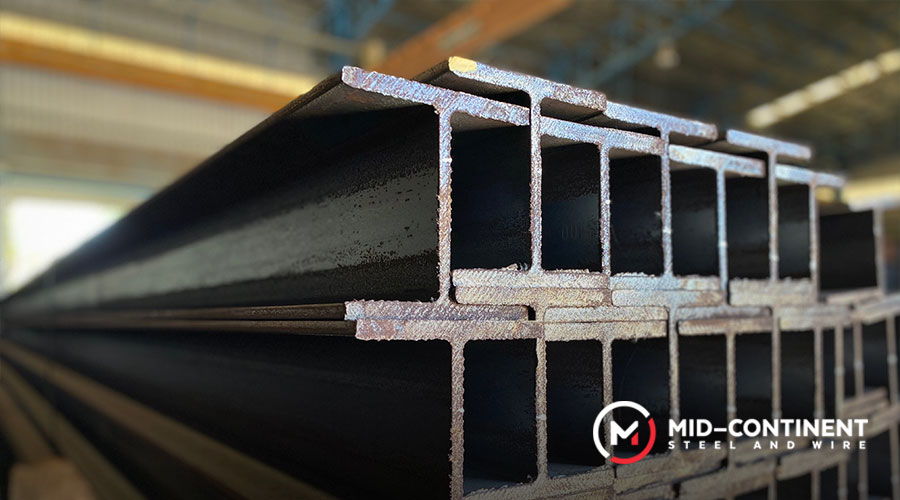

Also known as universal beams, H-beams, or W-beams, these are structural elements characterized by their distinctive I or H shape in cross-section. This design maximizes strength while reducing material usage, making them ideal for supporting heavy loads over long spans. They are widely used in construction and manufacturing due to their excellent load-bearing capacity, high strength-to-weight ratio, and torsional stability.

Main components of steel I-beams

The structure of an I-beam consists of flanges and the web. Flanges are the horizontal top and bottom sections that bear the load, the web is the vertical section that connects the flanges. This allows I beams to handle bending and shear stress.

Applications of steel I beams

I-beams are typically used as structural components in buildings and bridges, providing significant support and stability. They also serve as primary support trusses in building frameworks, helping to resist bending and shear forces. In industrial settings, they are used to create platforms and loading/unloading ramps. They can also be used for parking garages and industrial facilities such as warehouses and manufacturing plants.

Their versatility and strength make them a preferred choice for engineers and architects.

Types and classifications of steel I-beams

Steel I-beams can be classified based on various factors, such as cross-sectional shape and design, manufacturing and construction applications, and steel grades.

- Shape: Common shapes include wide flange beams and S-shaped beams. The term “wide flange” often refers to W-beams, but it can also describe I beams with wider flanges. Standard I-Beams or S-Beams feature tapered flanges that are thicker near the web and thinner at the edges, with a generous radius in the transition.

- Material: They are typically made from structural steel, but can also be formed from aluminum or other materials.

- Size and weight: I-beams are available in various sizes and weights, which are designated by their nominal depth and weight per foot (e.g., S12x50 indicates a beam with a depth of 12 inches and a weight of 50 pounds per foot).

Design considerations for steel I-beams

When designing with steel I-beams, several factors must be taken into account:

- Load capacity: The load capacity of steel I-beams depends on the beam’s material, cross-sectional dimensions, span length, type of load, and how the load is applied.

- Shear and bending stresses: Calculating the shear and bending stresses to ensure they remain within acceptable limits to prevent failure.

- Connection design: Designing connections between beams and other structural elements to ensure they can effectively transfer loads while maintaining structural integrity.

- Material properties: Considering the yield strength, ductility, and toughness of the steel.

- Construction type: Understanding the type of construction and how it affects beam selection and design.

Mid-Continent steel beams

Our beams are adaptable to different uses based on its shape, thickness, and mechanical properties, from structural reinforcement in commercial building projects.

S-BEAMS

- Standard Lengths: 20ft-60ft (Shorter cut lengths also available)

- Special Length: 50ft

- Grades: ASTM A36, ASTM A572-50, ASTM (A36/A572-50)

- Uses and Applications: Building construction, hoists, lifts, and many other uses.

WF-BEAMS

- Standard Lengths: 20ft-60ft (Shorter cut lengths also available)

- Grades: ASTM A572-50, ASTM A992, ASTM (A992/A572-50)

- Uses and Applications: Buildings construction, bridges, machinery, and many other uses.