Steel beams are structural elements used extensively in construction to support loads over long spans and resist bending and shearing forces. There are several types of steel beams commonly used in construction, each with specific characteristics.

Types of steel beams

Finding the right type of beam for your project depends on various factors. Steel beams come in many shapes and sizes and each of them is designed for a specific intention. Here are some of them:

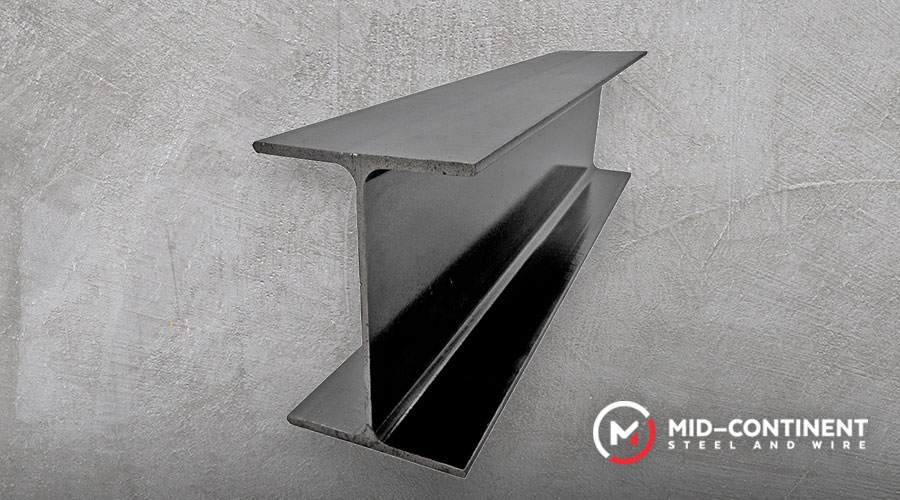

- I-Beams (or H-Beams): I-beams are shaped like the letter “I” in cross-section, with a horizontal top flange and a vertical web connecting the flanges. They are used for structural applications such buildings, bridges, and industrial facilities.

- Wide Flange Beams (W-Beams): Wide flange beams have wider flanges than standard I-beams, providing greater strength and stability. They have a profile similar to I-beams but with a wider top and bottom flange. They are seen in structural steel framing, columns, bridges, and industrial structures where heavy loads and long spans are required.

- Hollow Steel Section (HSS): HSS beams are made from hollow steel sections, typically square or rectangular in shape. They are used where a higher strength-to-weight ratio is required. You can find them in trusses, supports for curtain walls, and in situations where corrosion resistance is needed.

- Channel Beams: Channel beams have a U-shaped cross-section with straight legs and a perpendicular web between them. They are often used as structural supports in industrial and commercial buildings, support frames, roof purlins, and where the beam needs to be mounted onto another structure.

- Angle Beams (L-Beams): Angle beams have an L-shaped cross-section with two legs of equal or unequal length. They are used primarily as braces and supports in construction and engineering projects like bracing members, supports for frames and structures, and as lintels over openings.

- Tee Beams: Tee beams have a T-shaped cross-section with a horizontal top flange and a vertical web. They are used in bridge construction, piers, and where beams need to support heavy loads with minimal deflection.

- Composite Beams: Composite beams consist of a steel beam with a concrete slab cast over the top. This combination leverages the strength and stiffness of steel with the durability and fire resistance of concrete. They are used in floor and roof systems in multi-story buildings, bridges, and infrastructure where longer spans and higher load capacities are required.

Size of steel beams

The size of beams matters significantly in construction and structural engineering due to several factors that influence the performance and safety of construction projects. Choosing the right one is essential since a lot of them carry heavy loads and support large construction projects.

- Load-bearing capacity: The size of a beam affects its load-bearing capacity. Larger beams can support heavier loads and span greater distances. Engineers calculate beam sizes based on the anticipated loads, such as dead loads and live loads, to maintain structural integrity.

- Spanning capability: Beam size influences the maximum distance, or span, it can cover between support points without requiring additional support. Larger beams with greater depth or width can span longer distances, reducing the need for intermediate supports.

- Stiffness and deflection: The size and shape of a beam affect its stiffness and resistance to deflection. Larger beams typically have greater moment of inertia and are less prone to excessive bending, which helps maintain the structural integrity and stability of the building.

- Structural safety: Choosing the appropriate beam size is crucial for the safety of occupants and the longevity of the structure. Undersized beams may lead to structural failures, such as excessive deflection and sagging floors or roofs.

- Architectural considerations: Beam sizes can impact architectural aesthetics and design flexibility. Larger beams may require more space and affect ceiling heights or floor-to-ceiling clearance. Engineers work closely with architects to balance structural requirements with design preferences.

Mid-Continent Steel and Wire has the steel beams for your project

In the construction industry, structural beams are essential components. As a fully integrated steel manufacturer, we exercise tight quality control over all our processes to offer a superior line of beams. We have the equipment and technology for our customer project requirements.