The global steel industry is a major contributor to climate change, accounting for approximately 7% of all anthropogenic CO2 emissions worldwide. This is primarily due to the energy-intensive nature of production and its heavy reliance on carbon-based fuels. As the world grapples with these challenges, the steel sector faces both challenges and opportunities in reducing its carbon footprint.

Let’s dive into some ways in which steel producers are taking on environmental practices to lower this impact.

Key innovations in reducing carbon emissions

Key innovations are critical to significantly lower global steel emissions. Making efficiency improvements help cut greenhouse gas emissions, improve energy efficiency, and support a shift toward better industrial practices. These are some of the common advances:

- Utilization of renewable energy sources: Integrating renewable energy sources into steel production can dramatically reduce the industry’s reliance on fossil fuels. Solar, wind, and hydroelectric power can power electric arc furnaces and other production processes.

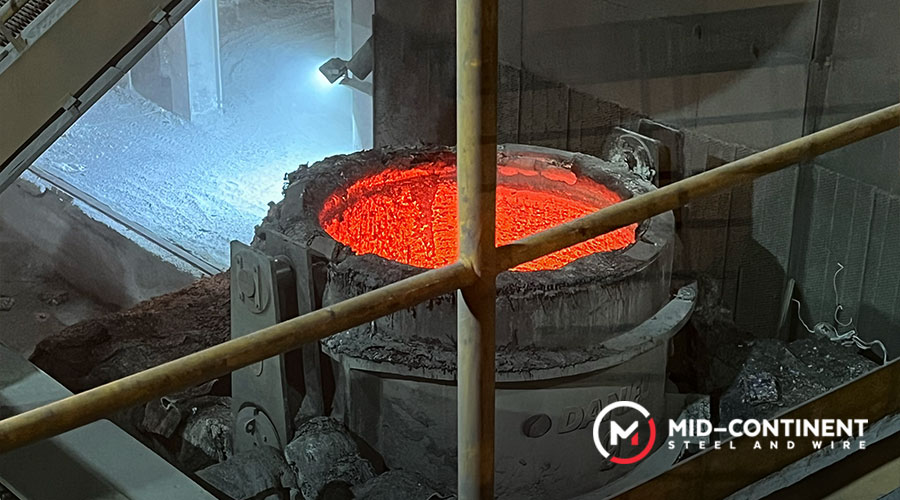

- Transitioning to electric arc furnaces: Electric arc furnaces offer a more energy-efficient alternative to traditional blast furnaces. Combined with renewable energy sources, they can significantly reduce the carbon intensity of steel production.

- Maximizing scrap metal use: Recycling plays a crucial role in reducing the steel industry’s carbon footprint. Increasing the use of scrap metal in production can lead to great energy savings and reduced raw material extraction.

Barriers to low-carbon transformation

The transition to low-carbon steel production faces significant challenges, despite technological progress and growing environmental urgency. The growing steel demand faces some challenges, these being two of the most common:

Economic considerations

The transition to low-carbon steel production involves significant upfront costs. New technologies, infrastructure upgrades, and process changes require substantial investments. Balancing these costs with the long-term benefits of sustainability is essential for the industry.

- 97% of our raw materials are recycled, supporting a circular economy and minimizing waste. Plus, your products will last a lifetime, without the need for constant repairs or replacements.

Fossil fuel dependence challenges

The steel industry’s deep-rooted dependence on fossil fuels, particularly coal, presents a major hurdle in the transition to low-carbon production. Iron ore plays a central role in the sustainability of steel manufacturing because it is the primary raw material used to produce steel. However, its extraction, transport, and processing are all carbon-intensive and environmentally impactful.

- MCSW as part of DEACERO, utilizes electric arc furnaces to melt recycled scrap steel, a method that significantly lowers carbon emissions compared to traditional blast furnaces. This approach results in only 0.36 tons of CO₂ emitted per ton of steel produced.

Initiatives towards greener manufacturing

The steel industry plays a key role in the construction sector. With 52% of steel used in building and infrastructure, there’s a significant opportunity for sustainable development.

The fact that steel can be recycled infinitely without losing its properties, provides a unique advantage in creating a circular economy. On top of this, various manufacturers have developed initiatives to guide the steel industry towards net-zero emissions and more sustainable practices.

Mid-Continent Steel and Wire’s contributions to sustainability

As the master distributor of DEACERO, all the products we offer and distribute are manufactured under an innovative production process. Neutrum® is DEACERO’s carbon-neutral steel product line. It’s carbon emissions are offset through verified nature-based carbon credits, making it one of the most sustainable steel options available.

Through the collection and recycling of scrap materials, we are able to produce high-quality steel in electric arc furnaces. It’s a more environmentally friendly alternative, generating far fewer CO₂ emissions into the atmosphere. As a result, we have achieved one of the most impressive decarbonization rates in the world. We are proud to have:

- 21 Recycling Centers in North America

- 97% of the raw material used in our production is recycled.

- 42% of the water used in our production undergoes a treatment process.

- 81% of the leftover in our production is recycled back into raw material.

- Only 0.36 tons of C02 is emitted for each ton of steel produced. 85% lower than the global average!

Choose solutions made from recycled steel and help reduce CO₂ emissions. We have a wide range of steel products that adapt to any kind of project with incredible quality, strength, and sustainable value. Check out our catalog and get in touch for more details.