As the demand for infrastructure and development continues to rise, the environmental impact of traditional construction practices has become a pressing concern. The construction industry increasingly embraces scrap steel recycling as a key strategy for building a more sustainable future. Steel is a highly sustainable material that can be fully recycled repeatedly without losing its strength or quality.

What makes steel recyclable?

Here are some reasons for supporting this sustainable practice:

- No degradation: Steel doesn’t degrade during the recycling process, allowing it to be reused indefinitely. Its high strength-to-weight ratio means it can withstand heavy loads without deformation.

- Versatility: Recycled steel can be used to produce different types and grades of steel products. It is one of the most versatile materials in construction and manufacturing, offering a wide range of applications.

- Durability: Recycled steel retains its strength, making it durable even for high-stress applications. It is suitable for use in environments exposed to moisture, chemicals, or extreme weather conditions.

The impact of recycling scrap steel

A great advantage of steel is that it can be recycled repeatedly without any loss in its strength or quality. Reprocessing scraps into new products can greatly benefit the environment by:

- Reducing carbon emissions: Using recycled steel drastically lowers energy consumption, around 74% less compared to producing new steel from raw materials. This translates into fewer greenhouse gas emissions, saving energy that would otherwise be used in producing new steel.

- Minimizing waste: By recycling scrap steel, the industry can divert significant amounts of waste from landfills, reducing their overflow and decreasing the environmental degradation associated with waste disposal.

- Conserving natural resources: Leaning into scrap steel recycling helps decrease the reliance on earth’s resources for manufacturing.

- Saving on costs: This also has financial advantages since melting down scrap steel requires significantly less energy compared to melting raw materials.

- Reducing production steps: Skipping the steps of mining, refining, and processing iron, which are energy-intensive processes in traditional steel production. Recycling steel is directly melted, reformed, and used in new products.

The steel recycling process

The steel recycling process involves several major steps, here’s how it works:

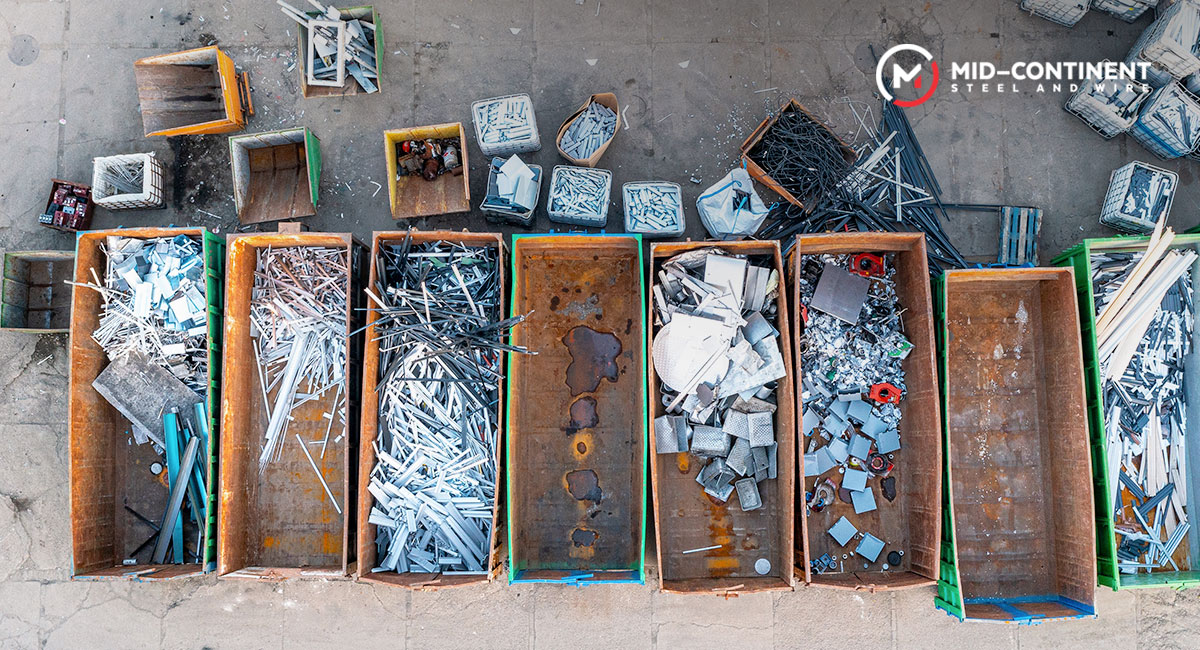

- Collection and sorting: Steel is collected from demolition or renovation projects. It is then sorted into different types based on the grade and alloy content (e.g., carbon steel, stainless steel, or rebar).

- Preparation: Any non-metallic materials are removed from the steel. This may involve processes like mechanical separation, magnetic separation, or chemical cleaning.

- Melting and refining: The sorted and cleaned steel scrap is melted down in a furnace. The most common method is electric arc furnaces (EAF), which use electrical energy to melt the scrap steel at high temperatures.

- Creating new steel products: Steel is cast into construction materials. In the construction industry, a significant portion of recycled steel is used to produce vital components in reinforced concrete structures, buildings, bridges, and other infrastructure.

Lean into sustainable building

The construction industry is increasingly adopting green building standards. Leading architects and engineers are prioritizing sustainable construction practices by incorporating recycled steel in their projects.

The use of recycled material helps buildings get green certifications such as LEED. This means a building meets specific sustainability standards, and recycled steel is a key component to achieving them.

At Mid-Continent Steel and Wire, integrating sustainability in our practices is of the utmost importance. Our manufacturing process is carefully designed to produce steel solutions that contribute to a greener future. Check out all of our products and start building strong projects!